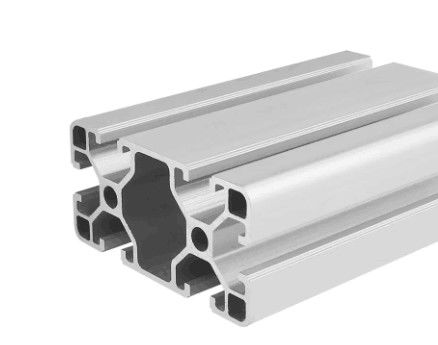

Custom CNC Sheet Metal Laser Cutting Welding Parts Stamping Service Aluminum Sheet Metal Punch Processing Fabrication

Description:

In sheet metal processing, shaping, stamping, and joining metal plates often involves the use of specialized tools known as stamping dies. These dies come in two main types: single dies and composite dies. Choosing the right type of die depends on various factors such as production costs, order volume, lead time, and specific project requirements. Typically, these dies have a lifespan ranging from 100,000 to 500,000 operations before needing replacement.

Specification:

|

Product Name

|

Cooper Stamped Sheet Metal Quality Metal Stamping Sheet Metal Fabrication

|

|

Material

|

Cooper/Carton steel/aluminum/brass/stainless steel

|

|

Color

|

Customized

|

|

Processing

|

Laser cutting/CNC Punching/CNC Bending/Welding/Painting/Assembly

|

|

Surface treatment

|

Power coating,zinc plated,Polishing, Plating, Brush, Skill-screen etc.

|

|

Drawing Format

|

CAD, PDF, SOLIDworks etc.

|

|

Certification

|

ISO9001:2008 CE SGS

|

|

|

pin gauge,caliper gauge, drop off test, vibration test, product lifecycle test, salt spray test, projector, coordinate measuring machine calipers, micro caliper, thread miro caliper, pass meter, pass meter etc.

|

Related Products

Our Advantages:

Easy to order, provide a variety of services

1. Customer testing: We do quality inspection and size report and sample confirmation before packaging.

2. Label printing: screen printing, laser marking and other surface treatment

3. Packaging: carton packed with polyethylene bag, according to the actual requirements of packaging.

4. Sample: We can provide free samples for you to test the quality.

5. Model making: We can make models according to your own design.

6. Quality assurance: If the product quality is not qualified, we will replace it by 1:1.

7. Delivery :2-5 days, if available.

Customer Comments

Payment and Delivery

Type of shipping

Package

FAQ

Q: Do you have any MOQ?

Reply: No limit. More quantity has better price, we will check the best price for you.

Q: What's the delivery time?

Reply: Generally within 7-15 days, we will arrange for you as soon as possible.

Q: what can you buy from us?

Reply: Metal Stamping/Toggle Latch/Casting/Clamp/Crate Clip/Server Chassis

Q: why should you buy from us not from other suppliers?

Reply: Established in 1998, Oriens Technology is specialized in precision metal stamping& casting, with wide-range production lines cover all kinds of application areas. Strict QC system, reasonable price, fast delivery and best service are all our advantages.

Q: Which shipping method do you usually use?

Reply: By train/sea DDP, by express, we can also ship with your own forwarder.

Q: How do I know if you have shipped my order?

Reply: Tracking number will be provided as soon as your order is shipped.

What does ORIENS do?

ORIENS dedicates to OEM metal stamping parts like brackets in different shapes, clips, clamps, hinges, toggle latches, metal cases, rf shielding parts, deep drawn parts for over two decades. With remarkable quality and competitive price, ORIENS gains

incomputable clients with stable business relationship.

Welcome to send inquiries to us, we will offer you the best solution.

ORIENS Company

ORIENS stands out as a premier business partner offering OEM and comprehensive ONE-STOP services for metal stamping parts and Investment Casting (lost wax) parts. Our capabilities extend to fulfilling diverse requirements for stainless steel, carbon steel, aluminum, brass, copper, bronze, and more, tailored precisely to customers' specifications, be it from drawings or original samples.

With a steadfast commitment to Integrity, Quality, and Competitive Prices, ORIENS consistently delivers excellence in every aspect of our service. Our dedicated technical and sales teams are primed to assist with your projects promptly and efficiently. From initial drawing design to final after-sales support, we ensure a seamless process encompassing quotation, sample checking, production, delivery, shipping, and more.

Our clientele spans across global markets including the US, Europe, Africa, South Asia, and beyond, attesting to our unwavering dedication to customer satisfaction and superior product quality. We eagerly anticipate the opportunity to forge a reliable partnership with you, working hand in hand to achieve remarkable success together!

How to contact us?

Send your inquiry details in the below for free sample, click send it now!

History: Founded in 1998

Employees: 300+ staff

Production Equipment: Automatic production lines

Certificate: ISO 9001

Main Products: Toggle latches, metal stamping parts,crate clips, pallet collar hinges, door lock strike plates, fan blades, custom hinges, etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!