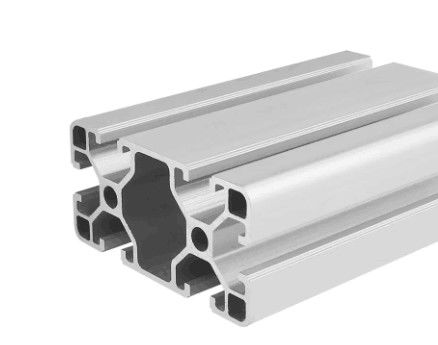

Customized Precision Metal Machining Services Aluminum Parts Die Casting

Description:

The process of creating a customized precision OEM cast iron part or aluminum metal die casting part involves a specialized technique known as die casting. This manufacturing process consists of melting metal and injecting it into a specially designed mold, then allowing it to cool and solidify before being ejected from the die. Die casting is an ideal choice for producing high-precision and complex parts, making it perfect for customized and precision OEM cast iron parts and aluminum metal die casting parts. These parts are commonly used in industries such as automotive, aerospace, and others, where precision and durability are essential.

At our company, we take great pride in providing our customers with high-quality and reliable die casting services. We have a team of experienced professionals and advanced equipment to ensure precision and accuracy in every part that we produce. Our exceptional customer service allows us to work closely with our clients to meet their specific requirements and needs. Whether you’re in need of customized precision OEM cast iron parts, aluminum metal die casting parts, or any other die cast parts, we’re dedicated to providing you with the quality and service that you need.

Specification:

| Product Name |

Customized Precision Metal Machining Services Aluminum Parts Die Casting

|

|

Surface Treatment

|

Anodizing,Sand blasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving

|

|

Sample

|

We can provide free samples.

|

|

Product Quality

|

2 times quality checking by QC before shipping. (On production line+ packing team checking)

|

|

Lead time after order placing

|

3-5days if on stock (mostly) , custom designs normal 25-35 days ( depend on your designs and bottle material)Usually 5-7days by express. 30-35days by sea if big quantity.

|

|

Product Certificate

|

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

|

| Usage |

Industry, Construction, Auto Parts

|

| Sample Confirmation |

Before starting mass production, we will send the pre-production sample to the customer for confirmation. We will modify the mold until the customer is satisfied. |

| Packaging Details |

Die casting parts will be packed in Corrugated carton, then put the cartons in wooden case. |

| Production Process |

CNC machining ,CNC turning, CNC milling, Drilling, Grinding, Wire-EDM cutting ,

Plastic Injection, Stamping, Die Casting

|

| Size |

Customized size according to drawings or samples |

Product Details:

Surface Treatment

At ORIENS, we take pride in delivering customized surface treatment solutions that are carefully tailored to address the individualized production needs of our clients. By leveraging cutting-edge technologies like precision casting, casting, and stamping, we are able to deliver high-quality and cost-effective solutions. Our comprehensive range of services, including galvanizing, electroplating, and spraying, guarantee that our solutions go beyond the industry standards, setting new benchmarks for exceptional quality. Our ultimate objective is to align with our clients' production objectives, constantly striving to achieve outstanding results that maximize their business outcomes. Connect with us today to see how our bespoke surface treatment solutions can position your organization to surpass limits and achieve untold success.

Our Advantages:

Easy to order, provide a variety of services

1. We take immense pride in our unwavering commitment to delivering the finest quality products, which consistently translate to exceptional excellence for our esteemed clientele.

2. Our labeling solutions prioritize customer convenience, and we have optimized our processes to ensure swift and seamless service delivery.

3. Each package we create is tailored to meet the unique requirements of our customers, reflecting our steadfast commitment to exceeding expectations with exceptional service.

4. To make informed decisions, we offer our valued patrons complimentary product samples for their evaluation.

5. Our exceptional product design services are the foundation of our competitive edge in the industry, setting us apart from our rivals.

6. To exemplify our commitment to excellence, all our products undergo rigorous quality checks to guarantee optimal performance and extended durability.

7. We firmly uphold our commitment to on-time delivery with reliable shipping services that guarantee product delivery within a maximum of 5 business days, surpassing customers' delivery expectations.

Customer Comments

Payment and Delivery

Type of shipping

Package

FAQ

Q: Do you have any MOQ?

Reply: No limit. More quantity has better price, we will check the best price for you.

Q: What's the delivery time?

Reply: Generally within 7-15 days, we will arrange for you as soon as possible.

Q: What can you buy from us?

Reply: Metal Stamping/Toggle Latch/Casting/Clamp/Crate Clip/Server Chassis

Q: Why should you buy from us not from other suppliers?

Reply: Established in 1998, Oriens Technology is specialized in precision metal stamping& casting, with wide-range production lines cover all kinds of application areas. Strict QC system, reasonable price, fast delivery and best service are all our advantages.

Q: Which shipping method do you usually use?

Reply: By train/sea DDP, by express, we can also ship with your own forwarder.

Q: How do I know if you have shipped my order?

Reply: Tracking number will be provided as soon as your order is shipped.

What does ORIENS do?

With over 20 years of experience in the industry, ORIENS has emerged as a distinguished original equipment manufacturer of metal stamping components. Our extensive product line spans metal cases, brackets, hinges, clamps, toggle latches, deep-drawn parts, and RF shielding parts. We are dedicated to delivering exceptional quality components at highly competitive prices, fostering long-lasting partnerships with our valued clientele. Our seasoned team of experts is committed to offering bespoke solutions to address all inquiries and concerns, prioritizing customer satisfaction. Benefit from our vast experience and expertise by contacting us today to discover how we can help accelerate your business to new heights of success.

ORIENS Company

As a reliable ONE-STOP OEM service provider, ORIENS is dedicated to catering to the diverse needs of our esteemed clients through exceptional metal stamping and investment casting components. We prioritize delivering bespoke solutions that align with your business's specific material requirements while ensuring affordability. Our competent team of professionals offers personalized guidance, comprehensive support, and end-to-end assistance, from product design to after-sales, ensuring that you achieve optimal outcomes. Our goal is to establish enduring partnerships with our global clients, fostering mutual growth and success. Benefit from our cutting-edge solutions and unmatched services to unleash your business's full potential. Contact us today to tap into our expertise and propel your enterprise's expansion.

How to contact us?

Send your inquiry details in the below for free sample, click send it now!

History: Founded in 1998

Employees: 300+ staff

Production Equipment: Automatic production lines

Certificate: ISO 9001

Main Products: Toggle latches, metal stamping parts,crate clips, pallet collar hinges, door lock strike plates, fan blades, custom hinges, etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!